Contact Us

Jethwa Industries House. 1,

Favourite Industrial Estate,

Masrani Lane,

Halay Bridge, Kurla (West),

Mumbai - 400 070,

Maharashtra, India.

Mobile No. : 98200 12620 /

98339 82323

Telephone : +91-22-2503 1955

Fax : +91-22-2503 1955

Multi-operational, body forming press for performing over 7 different functional operations in single stock, to form complete body.

Multi-operational, body forming press for performing over 7 different functional operations in single stock, to form complete body.

1) Both are folding.

2) Flange on top bottom.

3) Both sides' border and panel emboss

4) Letter embosses.

5)45 bend on one end.

6) Both end bending for

sides suitable to take over 5 different operations, heavy frame type, double press, complete with side flywheel.

7)Centre body bending.

Heavy duty structure, robust, steel fabricated, double crank type with phosphorous bronze bushing. The machine is heavy in construction with rigid design in conjunction to give great stability even at high speeds. The machine is used for cutting large sized sheets into pieces for half body blanks and top bottoms. The machine is treadle operated and equipped with stop attachment which must be adjusted to the correct size of required blanks. The finger guard fitted in front is for holding sheets. The shearing blades are made of quality steel for clean cutting. Operating pedals are fitted with springs made from high tension spring wire. A guillotine shear is always a useful object in a tin making factory.

The foot operated machine 'notch' or 'trim' the four corners of the half body blanks. It is necessary to cut four corners of each blank. Since a tin container has two body blanks which means eight corners must be notched. The machine is fitted with apparatus adjustable for different angles for flat corner cutting. The notching of the body blanks is absolutely necessary in the absence of which the container cannot be flanged and seamed. Beyond that 4 sheets can be notched at a time.

The foot operated machine 'notch' or 'trim' the four corners of the half body blanks. It is necessary to cut four corners of each blank. Since a tin container has two body blanks which means eight corners must be notched. The machine is fitted with apparatus adjustable for different angles for flat corner cutting. The notching of the body blanks is absolutely necessary in the absence of which the container cannot be flanged and seamed. Beyond that 4 sheets can be notched at a time.

The press is a robust design for undertaking heavy and constant work. The multi friction body paneling die sets fitted to the press. Represent the very latest, development in manufacturing of 15 kgs-18.5 litres square cans. Also the labour cost is reduced considerably. The multi friction body paneling die set is capable of fractioning 5 different junction operations of half body blanks in a single stroke, which are

The press is a robust design for undertaking heavy and constant work. The multi friction body paneling die sets fitted to the press. Represent the very latest, development in manufacturing of 15 kgs-18.5 litres square cans. Also the labour cost is reduced considerably. The multi friction body paneling die set is capable of fractioning 5 different junction operations of half body blanks in a single stroke, which are

1) double border embossing,

2) and folding for horning,

3) upper lower flange for double seaming,

4) one end bend of 45 degrees and also

5) letter embossing on blanks for procedure trade marks.

The body blanks should be bended in right angle of 90 c. before they are side-joint on double horn press. The machine is fitted with adjustable gauges for necessary adjustment to get the correct size of blank. Each blank must be bent exactly in the middle. Bending tools are changeable in case there is difference in corner radius.

The body blanks should be bended in right angle of 90 c. before they are side-joint on double horn press. The machine is fitted with adjustable gauges for necessary adjustment to get the correct size of blank. Each blank must be bent exactly in the middle. Bending tools are changeable in case there is difference in corner radius.

The press is fitted with double horn tooling, close to both the opposite corner side seams for large outputs at one stroke. The multi horn tooling is equipped with self stopper and two side supporting rockets to ensure the perfect alignment while operating the press.

The press is fitted with double horn tooling, close to both the opposite corner side seams for large outputs at one stroke. The multi horn tooling is equipped with self stopper and two side supporting rockets to ensure the perfect alignment while operating the press.

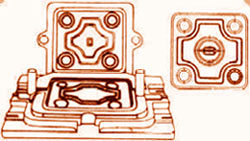

The heavy duty press fitted with stamping and embossing bottom die set combination, is operated in a stroke. The combined operating tools are mounted on pillar die set to give extreme rigidity and to facilitate setting. The maintenance of dies operating in these conditions is very considerably reduced.

The heavy duty press fitted with stamping and embossing bottom die set combination, is operated in a stroke. The combined operating tools are mounted on pillar die set to give extreme rigidity and to facilitate setting. The maintenance of dies operating in these conditions is very considerably reduced.

The machine frictions the double seams on top and bottom to the bodies one and at a time. The machine is equipped with respective closing chuck which is already built in the machine. The machine is run with two seaming rollers frictioning single double operation. Double seam cans are effected by operating two rollers, thus doubling their thickness and giving additional strength on this machine and effecting the economy of solder.

The machine frictions the double seams on top and bottom to the bodies one and at a time. The machine is equipped with respective closing chuck which is already built in the machine. The machine is run with two seaming rollers frictioning single double operation. Double seam cans are effected by operating two rollers, thus doubling their thickness and giving additional strength on this machine and effecting the economy of solder.

Home | Profile | Machinery | Clients | Quality | Awards | Contact Us | Make Enquiry