Contact Us

Jethwa Industries House. 1,

Favourite Industrial Estate,

Masrani Lane,

Halay Bridge, Kurla (West),

Mumbai - 400 070,

Maharashtra, India.

Mobile No. : 98200 12620 /

98339 82323

Telephone : +91-22-2503 1955

Fax : +91-22-2503 1955

The complete range of semi-automatic machinery and equipments for producing drum barrel and buckets in various ranges for packing edible oil, paint, chemical, petrochemical and petroleum products. The importance of our machines lies in the modern and functional design based on many years of development, finest workmanship backed by a team of first class craftsmanship. To day the firm is a leader in steel metal machinery, which not only covers a range of drum barrel and buckets plants but also tin plate container manufacturing machinery plant. We export to the sophisticated world markets, a proof of our top quality and superior craftsmanship.

This machine is required for cutting sized body blank & top bottom blanks from a sheet or a coil. The basic structure is steel fabricated that gives it an extra strength and rigidity. for smooth & trouble free operation, an appropriate lubricating system is provided everywhere. The shearing blades are made out of best quality material, hardened and ground to its best standard, both the blades are reversible type so that all the four edges can be utilized, giving the blades and extra lift. All the moving parts (Bushing) are made up of phosphorus bronze. the maximum speed is given to achieve more production.

This machine is required for cutting sized body blank & top bottom blanks from a sheet or a coil. The basic structure is steel fabricated that gives it an extra strength and rigidity. for smooth & trouble free operation, an appropriate lubricating system is provided everywhere. The shearing blades are made out of best quality material, hardened and ground to its best standard, both the blades are reversible type so that all the four edges can be utilized, giving the blades and extra lift. All the moving parts (Bushing) are made up of phosphorus bronze. the maximum speed is given to achieve more production.

Edge grinding is very special operation in manufacturing of Drums & Barrels, because some amount of material is to be removed from the edges of the body which give advantages to A) Welding operations 9removes dirt, oiliness etc), extra strength to the weld and a leak proof joint. B) Flanging operation. C) End seaming operation (lesser thickness of side seam overlap). Maximum parts of the machine ate steel fabricated. It can absorb all the jerks & vibration caused due to the grinding wheel. Proper dressing arrangement is for smooth grinding. the entire machine is divided in 3 parts as A) Centre table on fixed guide rails by means of pneumatically operated long cylinder. B) Right hand side grinding unit. C) Left hand side grinding unit. All the tree units are properly assembled; micro setting arrangement is given for maintaining highly precise gap between the grinding wheels.

Edge grinding is very special operation in manufacturing of Drums & Barrels, because some amount of material is to be removed from the edges of the body which give advantages to A) Welding operations 9removes dirt, oiliness etc), extra strength to the weld and a leak proof joint. B) Flanging operation. C) End seaming operation (lesser thickness of side seam overlap). Maximum parts of the machine ate steel fabricated. It can absorb all the jerks & vibration caused due to the grinding wheel. Proper dressing arrangement is for smooth grinding. the entire machine is divided in 3 parts as A) Centre table on fixed guide rails by means of pneumatically operated long cylinder. B) Right hand side grinding unit. C) Left hand side grinding unit. All the tree units are properly assembled; micro setting arrangement is given for maintaining highly precise gap between the grinding wheels.

The machine serves to roll all sorts of tin bodies and it has a very high output. It can be operated easily and can be adjusted rapidly for tin bodies of various diameters. The rolls are of finest quality steel and run on gunmetal bearings.

The machine serves to roll all sorts of tin bodies and it has a very high output. It can be operated easily and can be adjusted rapidly for tin bodies of various diameters. The rolls are of finest quality steel and run on gunmetal bearings.

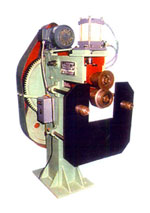

The rocker arm spot welding machine is an important machine in manufacturing Drums & Barrels. It is better to give some spots to the body sides before side seam welding operation. The machine can also be used for spot welding the handles etc., this machine is specially designed with a longer arm, bettr rated transformer & electronic timer, also given are various tapping to transformer for welding current selection enabling universal use.

The rocker arm spot welding machine is an important machine in manufacturing Drums & Barrels. It is better to give some spots to the body sides before side seam welding operation. The machine can also be used for spot welding the handles etc., this machine is specially designed with a longer arm, bettr rated transformer & electronic timer, also given are various tapping to transformer for welding current selection enabling universal use.

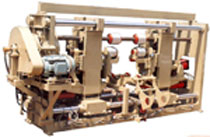

The illustrated model is for side seaming to the full-length of the hollow drum and barrel body. Machine body is reinforced fabricated steel structure with a heavy duty transformer used as the main power source, for continuous welding operations. The machine is equipped with upper and lower weld wheel assembly, water cooling system and built in welding transformer.

The illustrated model is for side seaming to the full-length of the hollow drum and barrel body. Machine body is reinforced fabricated steel structure with a heavy duty transformer used as the main power source, for continuous welding operations. The machine is equipped with upper and lower weld wheel assembly, water cooling system and built in welding transformer.

This machine gives beading to the drum or the barrel. This bead gives an extra strength to the body cell.It also contains sets of segment made out of finest quality heat treated ateel along with hydraulic power pack of all standard parts, high quality flexible tubing, and logic & control panel. Hydraulic cylinder etc. of this machine is very fast & the rejection rate is absolutely nill compared to rotary type bead machine. A seperate power pack is provided. In case of lower production rate, single tooling bead expander can be used. Double beading machine gives both beads at one stroke. Normal, unskilled operator can also operate this machine.

This machine gives beading to the drum or the barrel. This bead gives an extra strength to the body cell.It also contains sets of segment made out of finest quality heat treated ateel along with hydraulic power pack of all standard parts, high quality flexible tubing, and logic & control panel. Hydraulic cylinder etc. of this machine is very fast & the rejection rate is absolutely nill compared to rotary type bead machine. A seperate power pack is provided. In case of lower production rate, single tooling bead expander can be used. Double beading machine gives both beads at one stroke. Normal, unskilled operator can also operate this machine.

This machine is required for giving corrugation to the drum or the barrel. The illustrated model is a single stage corrugating machine where in one operation, we get a half body after turning in next operation we get another half body, this extremely silent, heavy duty & stable machine uses a specially designed gear box. Its strong drive is the main feature of this machine & the tooling is made up of best quality steel. Pneumatic cylinder is also given a heavy duty, so that the machine will minimize the jerks while overlapping of body drums & barrels. For various diameters a separate tool is not required.

This machine is required for giving corrugation to the drum or the barrel. The illustrated model is a single stage corrugating machine where in one operation, we get a half body after turning in next operation we get another half body, this extremely silent, heavy duty & stable machine uses a specially designed gear box. Its strong drive is the main feature of this machine & the tooling is made up of best quality steel. Pneumatic cylinder is also given a heavy duty, so that the machine will minimize the jerks while overlapping of body drums & barrels. For various diameters a separate tool is not required.

This machine is required for giving flange to the drums or barrel, by changing the rollers, the same machine can be used for single beading too. The illustrated model has flanging tool where in one stroke, we get one side flanging & by turning the body we get another side flanging. body is fabricated with heavy dutry gear & very stable structural design gives trouble free operation. Main features of this machine are strong drive, heavy duty pneumatic cylinder, hardened & ground tooling; this all together gives jerk free operation which is essential for best quality flanges, ultimately better flange gives better leak proof end seam. For different diameters, separate tools are not required.

This machine is required for giving flange to the drums or barrel, by changing the rollers, the same machine can be used for single beading too. The illustrated model has flanging tool where in one stroke, we get one side flanging & by turning the body we get another side flanging. body is fabricated with heavy dutry gear & very stable structural design gives trouble free operation. Main features of this machine are strong drive, heavy duty pneumatic cylinder, hardened & ground tooling; this all together gives jerk free operation which is essential for best quality flanges, ultimately better flange gives better leak proof end seam. For different diameters, separate tools are not required.

The machine is required for giving flange to the drum or the barrel. For getting good end seam, proper even flange is essential. This machine contains two flanging tools made out of good quality steel, which are heat treated and ground. It also has a separate hydraulic power pack of all standard parts, highly flexible tubing, logic, and control [panel, high quality hydraulic cylinder etc. The main advantage in this machine is that rejection rate is almost nil and gives both the flange simultaneously, it also gives very fast trouble free production, and unskilled operator also can operate this machine. operation is very safe because drum does not rotate. We get even flange and very precise diameter of drum and barrel body, no bucking, no unevenness of flange, no wrinkle to flange (usually all this defects are experienced in rotary flanging machines).

The machine is required for giving flange to the drum or the barrel. For getting good end seam, proper even flange is essential. This machine contains two flanging tools made out of good quality steel, which are heat treated and ground. It also has a separate hydraulic power pack of all standard parts, highly flexible tubing, logic, and control [panel, high quality hydraulic cylinder etc. The main advantage in this machine is that rejection rate is almost nil and gives both the flange simultaneously, it also gives very fast trouble free production, and unskilled operator also can operate this machine. operation is very safe because drum does not rotate. We get even flange and very precise diameter of drum and barrel body, no bucking, no unevenness of flange, no wrinkle to flange (usually all this defects are experienced in rotary flanging machines).

This press whether pillar type or fix type all are designed to suit for their particular functions & these presses can be utilized for cutting, blanking, piecing & embossing on sheet, We offer, embossing die as well as compound (cutting embossing type dies) .These presses are compatible with both type of dies while designing of these presses, the things that have been taken care of are heavy structure cross section, rigidity, stability & excess continues production.

This press whether pillar type or fix type all are designed to suit for their particular functions & these presses can be utilized for cutting, blanking, piecing & embossing on sheet, We offer, embossing die as well as compound (cutting embossing type dies) .These presses are compatible with both type of dies while designing of these presses, the things that have been taken care of are heavy structure cross section, rigidity, stability & excess continues production.

Introduction

We present to you through this catalogue, the complete range of Semi-Automatic Machinery & equipments for producing Drum-Barrel & Buckets in various ranges for packing Edible Oil, Paint, Chemical, Perto-chemical and Petroleum products.

The importance of our machines rest on the modem and functional design based on many years of development, finest workmanship backed by a team of first class craftman.

Today the firm is a leader in sheet Metal machinery, which covers a range of not only Drum-Barrel & Buckets plants but also Tin-plate container manufacturing machinery plant.

The firm exports to the sophisticated world markets, a proof of top quality & superior craftmanship. All products, described of illustrated are subject to change without notice.

Semi Automatic type, where the component to be placed on the table the chuck will come out with carry component and start rotating top spring loaded support will always be pressing the component so that the component formally sticks with chucks after that automatically one curling roller will come and curl the component the component on machine & removing of the same is manual.

Semi Automatic type, where the component to be placed on the table the chuck will come out with carry component and start rotating top spring loaded support will always be pressing the component so that the component formally sticks with chucks after that automatically one curling roller will come and curl the component the component on machine & removing of the same is manual.

This machine is required for seaming of top bottom with body. We can also get triple seaming from this it, where two seaming rollers (made out of good quality steel duly hardened & ground) come one after another resulting in strongest leak proof seaming. On special order, ejection of solution can be incorporated. With the help of following equipments: Foot operated switch, location clogs, smooth steady rotating table pneumatic cylinders, limit switch, logic control, power pack. Table stroke hydraulic cylinder, electro magnetic clutch brake unit strong enough, chuck drive, and proper grooved seaming roller assembly.

This machine is required for seaming of top bottom with body. We can also get triple seaming from this it, where two seaming rollers (made out of good quality steel duly hardened & ground) come one after another resulting in strongest leak proof seaming. On special order, ejection of solution can be incorporated. With the help of following equipments: Foot operated switch, location clogs, smooth steady rotating table pneumatic cylinders, limit switch, logic control, power pack. Table stroke hydraulic cylinder, electro magnetic clutch brake unit strong enough, chuck drive, and proper grooved seaming roller assembly.

Main features of this machine are:

• Best ever drive, containing electromagnetic clutch crack, heavy duty crown and double bearing on vertical shaft, bush as well as roller bearing on both ends. Also given is the thrust bearing for rigidity and stability.

• Hardened Chuck, very hard ground seaming.

• Solid state electronic logic control.

• Adjustable stroke hydraulic cylinder for both operations of quick and micro fine seating.

• By pass system for semi auto mode and manual open while seating.

• Separate individual functioning of each and every part.

• Free from mechanisms make the machine absolutely maintenance free.

• Quick changing of change parts shift.

Home | Profile | Machinery | Clients | Quality | Awards | Contact Us | Make Enquiry